Mechanical Sub-Team Exercises and Resources

Overview

The Mechanical Sub-Team is responsible for assembling and maintaining the mechanical components of the robot. These team members are in the pit at competitions and are responsible for repairing any broken mechanical systems. This team works with hand tools and mechanical drive systems such as chain drives, belt drives, gearboxes, and swerve drive modules.

Fasteners

Socket Head Screws

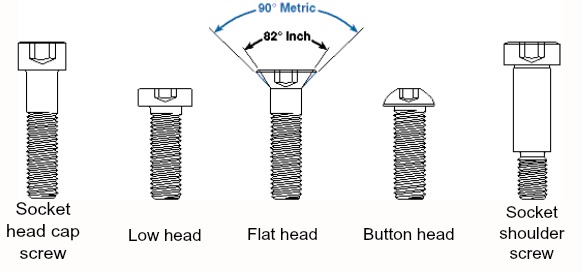

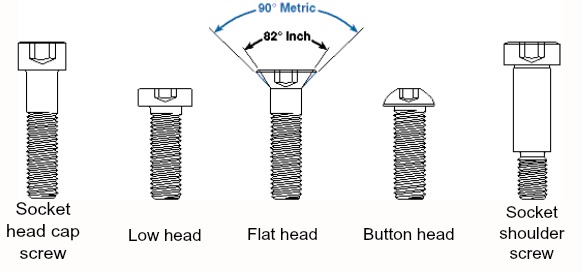

FRC robots usually use either socket head cap screws or button head screws due to their strength and ease of use. Socket head cap screws are the strongest type of screw. Button head screws have a lower and wider head and are good when holding thin sheet metal or when the lower profile is needed.

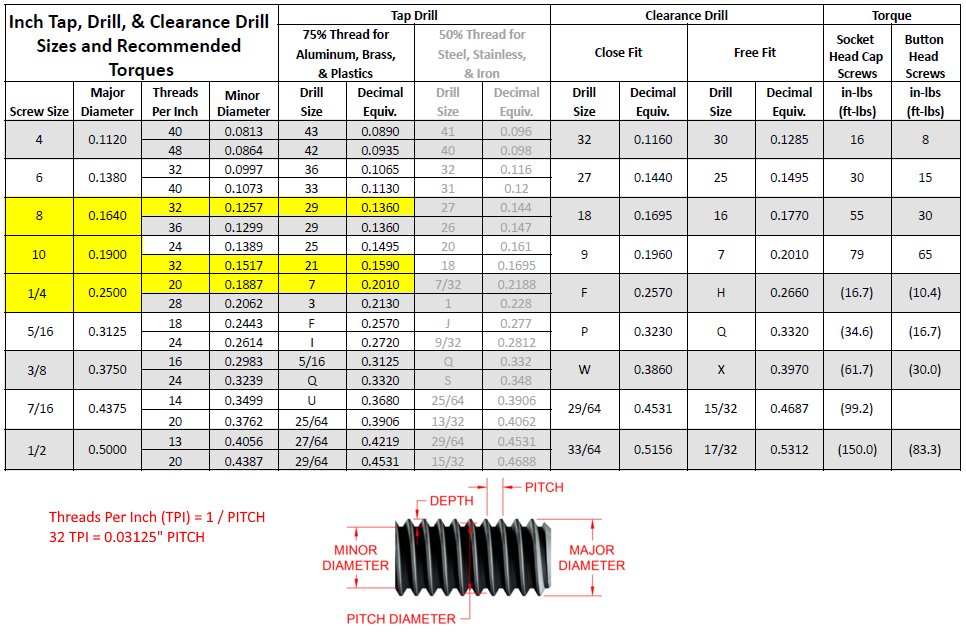

We almost always use Inch (or English) threaded fasteners. Inch fasteners come in several diameters and two main thread pitches (coarse and fine). Fastener diameters are fractions (like 1/4", 5/16", etc.) for diameters 1/4" or greater and they are denoted by numbers in the smaller diameters (#10, #8, #6, etc.). A "Drill and Tap Chart" shows the important dimensions of each size of bolt. We mainly use the Unified National Coarse (UNC) threaded bolts except for #10 diameter for which we use Unified National Fine (UNF) threads (#10-32).

If you are working with a #10-32 bolt then Figure 2 will tell you that the major diameter of the bolt will be 0.1900", the minor diameter is 0.1517" (not really used much), the drill size needed to tap threads is a #21 drill bit (0.1590"), and a close fit hole would be drilled with a #9 drill bit (0.1960"). The chart also shows both the coarse and fine thread sizes for each screw size and the maximum torque for both socket head screws and button head screws. For example, a 1/4" screw comes in either a 1/4-20 UNC thread (coarse thread) or a 1/4-28 UNF thread (fine thread). You would drill a #7 hole for a 1/4-20 bolt and a #3 drill for a 1/4-28 bolt. You would also drill a #F drill size for a close fit and you can torque a 1/4" socket head screw to 16.7 ft-lbs and a 1/4" button head screw to 10.4 ft-lbs.

Thread Locker (LOCTITE)

Thread locker is basically modified super glue that is applied to the threads of a fastener before it is assembled and then hardens to prevent the fastener from coming loose due to vibration. Thread locker comes in three main colors that indicate how strong it is.

RED Thread Locker (LOCTITE 263) is high strength and considered PERMANENT and should only be used when a fastener will not be removed EVER. It is not used very often.

BLUE Thread Locker (LOCTITE 243) is medium strength and is removable with normal hand tools. It should not be used on very small screws (e.g. #6 or #4). This is the most commonly used thread locker.

PURPLE Thread Locker (LOCTITE 222) is low strength and can be used on very small fasteners but it will not hold large fasteners well.

There are several types of GREEN Thread Locker such as LOCTITE 294 which is a medium strength wicking grade that will penetrate a thread after assembly. Another GREEN product is LOCTITE 609 which is a medium strength compound used to lock press-fit gears and bearings onto a shaft such as the gear for the NEO steering motor on the SDS MK3 swerve drive modules.

Drive Systems

A great deal of very good information can be found in the WCP FRC Build System documenation.

Belt Drives

Refer to Design Sub-Team — Belt Drives

Chain Drives

Roller chain used in FRC comes in two sizes: #25 chain and #35 chain. Roller chain is composed of inner links and outer plates. Roller chain can be shortened using a chain breaker tool that is used to press one of the pins out from one side of the outer plate and far enough to clear the inner link. Only even multiples of pins can be in a chain unless a half link (or 1.5 link) is used. Half links require the use of a very small cotter pin whereas 1.5 links do not.

(see also Design Sub-Team — Chain Drives)

Gear Drives

Refer to Design Sub-Team — Gear Drives